X? Advantages

1、Affordable

2、Quick, Convenient, Accurate Profiling

3、Easy to Use Software

4、Reliable, Robust Hardware

5、24 Hour Customer Support

6、KIC Profiler X? datasheet

7、KIC Profiler X? A4 size datasheet

Robust and Compact Hardware with 2 Year Warranty

This new and improved thermal profiler hardware is designed to withstand the roughest and toughest daily handling. In addition, the electronic circuitry has been changed to tolerate a higher level of voltage spikes

that occur occasionally in some ovens and wave solder machines. KIC is putting its money where its mouth is by offering a standard two year warranty on this durable profiler.

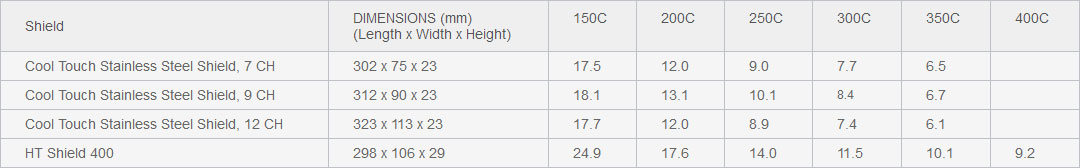

The X?? thermal profiler is available in 7, 9, and 12 channel versions using standard type K thermocouple connectors. Acquiring more data in a small unit is only the beginning. The X?’s industry leading performance provides better data acquisition to precisely identify what is going on with each thermal profile and process in the factory. Thermal profile data are conveniently transferred to your computer via a USB connection. The X?’s RF version transfers the profile data in real time to the PC via wireless radio frequency transmitters. Standard AAA batteries power the X? and you have the option of using regeable batteries if you prefer. The X? is also powered via the USB cable when connected to a computer, bypassing the batteries, thus extending the duration of their use.

Data Intelligence Software

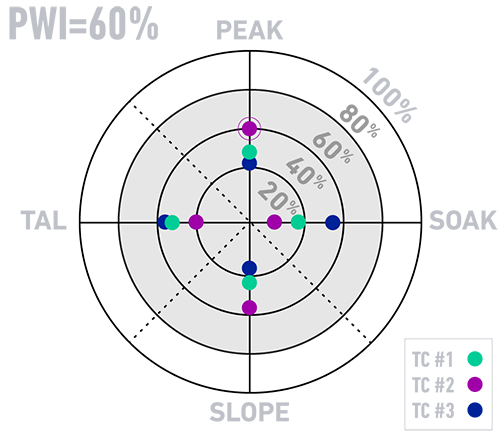

The X?’s thermal profiling software uses a modern, graphical interface that quickly and intuitively guides you through the task of profiling. All your critical profile and process data are measured including slope, peak temperature, time above liquidous, etc. In addition, the software measures the Process Window Index? (PWI) statistic. The PWI mathematically and objectively identifies your profile’s ‘fit’ to the established process window. A PWI less than 100 indicates an in-spec profile. The PWI is lower as your process is centered within the process window. Therefore, the lower your PWI, the deeper in the sweet spot of the process window. The PWI also instantly reveals where your process or the oven needs to be adjusted. Manual prediction capability comes standard with the X? allowing you to instantly view the expected change in the profile to changes in the oven setpoints. The X? dual mode includes the passive profiling recording functionality and the active oven setup and process optimization capability. The Navigator Power? software feature automates process improvement and equipment/machine optimization for you and ships standard with the X?. Within seconds, the Navigator Power will identify the single best oven setup based on your choice of 3 optimization criteria.

1、Center of the process window

2、Maximum conveyor speed

3、Minimum electricity use

The X? thermal profiler also comes standar with SPC ting software that helps reveal changes in the profile over time. The X? hardware and software establish a new generation of profiler to improve your equipment’s production quality, productivity, and documentation.

Datalogger Model: data are downloaded to the computer through a USB cable after the run.

Dual Unit Model: data are sent to the computer in real-time during the run. Data are also stored internally for USB download after the run.

Note: The Profiling Software may interface directly with some oven controllers, eliminating the need for manual setpoint data entry. Please consult your oven supplier for availability. The Profiling Software is dongle protected. Accuracy based on factory calibration.

The Process Window Index

Profiling Reduced to a Single Number

The PWI measures the profile’s fit to the process window in a mathematical and objective manner by using a single number. This aids in optimizing the process by comparing and ranking alternative profiles in terms of their fit to the available process window. The lower the PWI, the more efficient and stable the process! (See the PWI data sheet for a detailed explanation)